Manufacturing Strength

Manufacturability

① Mounter-Panasonic NPM

② Post-solder paste-SPI check

③ Reflow soldering in ten-temperature zone, with AOI inspection after the furnace

④ Three-in-one customer display simulation test

⑤ Process turnover is anti-static turnover box

⑥ The packaging for special knife card + anti-static bubble bag

⑦ 100% bare board test, high pressure, aging and comprehensive ATE test in the whole process

Capacity

① SMT capacity 120 PCS/H(PCB size below 500*310mm)

② Mounter: NPM-W2 (Panasonic)

③ Solder paste printing detection SPI

④ Reflow soldering

⑤ Reflow soldering AOI equipment

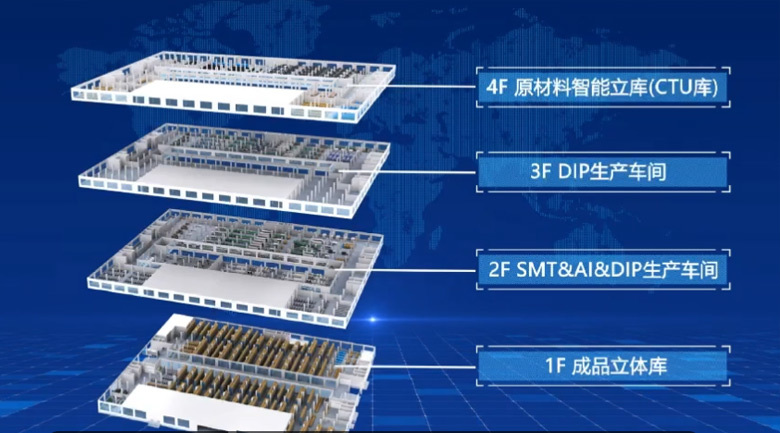

⑥ The new plant will be put into use in 2025 to increase production capacity.

⑦ The new factory implements MES/ERP/SCM/FDC/PLM system to improve efficiency, improve quality, reduce costs and meet the increasing demand of customers for sex and price.

Capacity and Manufacturability

Panasonic NPM-W2 Pick and Place Machine

Solder Paste Printing Inspection (SIP)

Reflow soldering

Reflow Soldering AOI 14

Mobile:13823666684

E-mail:sales@sourceleader.com.cn

Address: 6th Floor, Building T4, Haigu Science and Technology Building, Luozu Community, Shiyan Street, Bao 'an District, Shenzhen City, Guangdong Province